Hortonium 1: The Smart Choice for Ammunition Manufacturers

When we set about creating Hortonium 1, we first had to understand why Lead has been such a popular material in ammunition for several reasons, primarily due to its unique combination of properties that make it ideal for bullet and shot production:

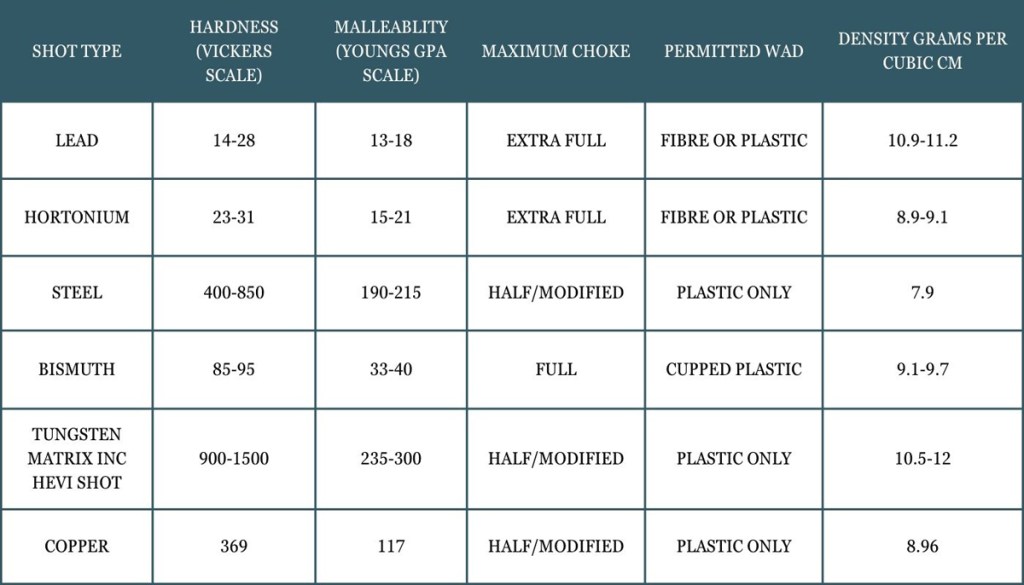

- High Density: Lead is a very dense metal, which gives it significant mass in a small volume. This makes lead bullets highly effective at retaining kinetic energy and penetrating targets. The high density also contributes to effective ballistics, allowing for better momentum retention and range. Hortonium is slightly lighter, although a slight increase in shot size easily remedies this.

- Malleability: Lead is a soft and malleable metal, which allows it to deform upon impact. This deformation, known as “mushrooming,” increases the bullet’s diameter as it enters a target, creating a larger wound channel, which is desirable for hunting and defensive applications. Hortonium can be blended to suit a range of malleabilities.

- Low Melting Point: Lead has a relatively low melting point (about 327.5°C or 621.5°F), which makes it easy to cast and form into bullets. This allows for efficient and straightforward manufacturing processes, which is especially important for mass production. Hortonium has a slightly lower melting point which reduces production costs further.

- Good Ballistic Performance: Lead’s combination of density and malleability allows for consistent ballistic performance. Lead bullets typically maintain their velocity and accuracy well, making them effective for both hunting and target shooting. The tests with Hortonium have identical results.

- Tradition: Lead has been used in ammunition for centuries, so its long history and established role in ballistic design have contributed to its continued use. Many firearms were specifically designed around the properties of lead projectiles. Therefore Hortonium only requires very slight changes to achieve the same results.

However, despite these advantages, lead’s toxicity and environmental impact have driven efforts to find alternative materials like Hortonium, as lead ammunition can contaminate soil, water, and wildlife. This has led to growing regulations and bans in many regions, pushing for eco-friendly alternatives. You can see from the table below how Hortonium 1 alloy compares closely in both density and malleability.

The video below showcases a drop test comparing Hortonium with Lead, Steel, and Bismuth. Watch the results and see the difference for yourself. Bismuth shot advocates often claim that it doesn’t shatter, but metallurgical tests tell a different story. In fact, the Royal Society of Chemistry classifies Bismuth as “brittle.” While some attempt to improve its performance by alloying it with tin, these elements do not bond at the molecular level, meaning they can fail under the high pressures of certain loads or impacts. The video below highlights this perfectly, featuring a premium Bismuth UK cartridge retailing at £1,600 per thousand. Hortonium offers a superior, durable alternative that withstands such pressures and maintains performance.

Lead’s inherent softness, due to its face-centered cubic lattice structure, makes it too weak on its own for use in high-pressure environments like shot. Traditionally, adding antimony and arsenic strengthens the structure by transforming it into a close-packed lattice, allowing lead to form perfect spheres that withstand the pressure in shot form.

Hortonium 1 replicates this same molecular structure found in lead shot, offering the same durability and performance without the environmental drawbacks of lead. With Hortonium 1, you get the same reliable performance, precision, and quality, making it the ideal lead-free alternative for ammunition manufacturers looking to stay ahead of the curve.

In developing Hortonium, we focused on seamlessly integrating it into the existing production techniques used for small-caliber ammunition. Most small-caliber bullets are formed from lead wire on large coils and then stamped by various methods. Hortonium can be extruded into wire of the most common gauges used in these processes, ensuring a smooth transition for manufacturers.

This offers a significant cost advantage—switching to Hortonium wire is far more economical and practical than investing heavily in new machinery to produce copper alloy bullets. By adopting Hortonium, you can enhance your product line without incurring the massive capital expenditure required for alternative materials.

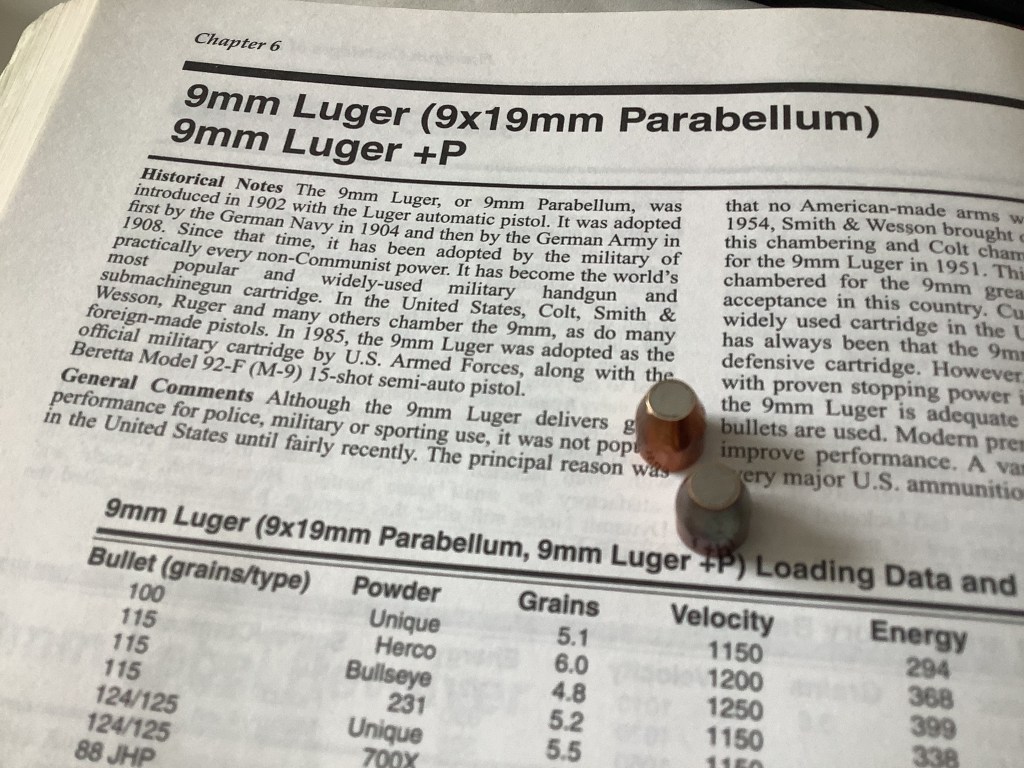

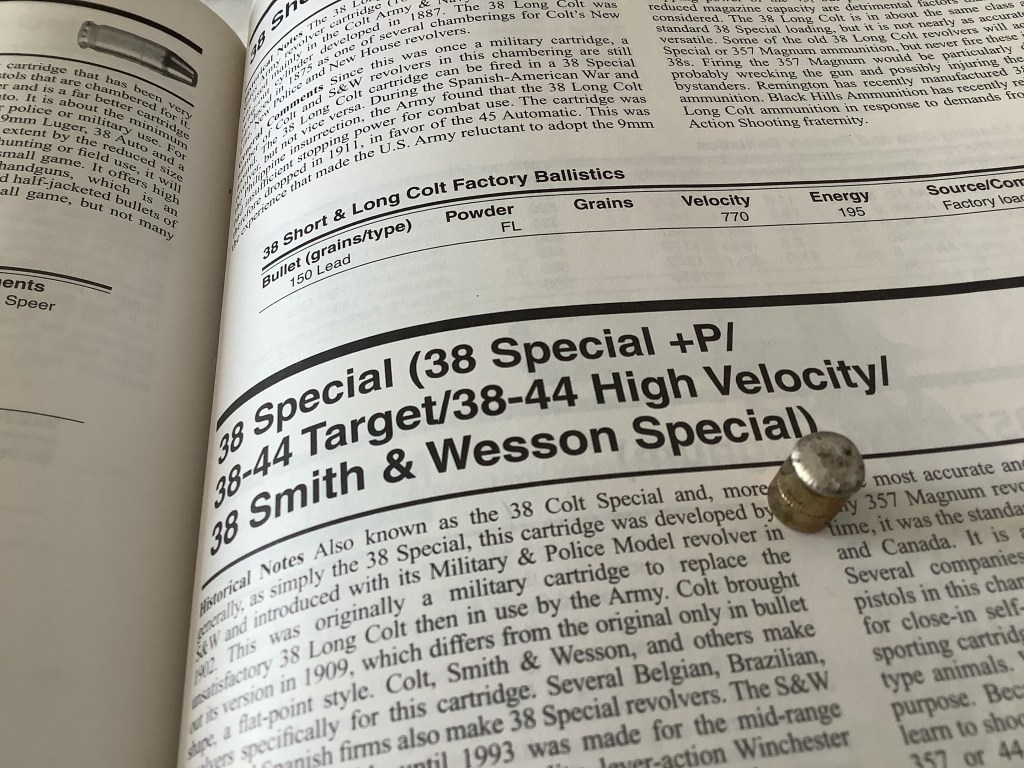

We’ve rigorously tested Hortonium across 15 different calibers, including popular rounds like .22LR (even subsonic and 40-grain), .243, .270, .308, and .38 Special. In every case, Hortonium performed just like lead, delivering the same accuracy, grouping, and penetration in ballistic gel tests. Hortonium gives you the lead-like performance your customers expect, with the added benefit of being an eco-friendly and cost-efficient solution.

Hortonium 1 – Small Arms Ammunition

When we set about creating Hortonium 1, we paid particular attention to the current production techniques normally deployed in the manufacturing processes of the various small arm calibres. Most smaller calibre bullets are formed from lead wire on large coils and then stamped by various methods Hortonium can be extruded into wire of the most common gauges used in these manufacturing processes.

This is important from the cost of manufacture for any ammunition producer, switching to Hortonium wire vs traditional lead wire is far more cost effective and easier than huge capital expenditure on new machines to create copper alloy bullets etc.

We have tested some 15 different calibres including 22LR (yes 40 grain plus and subsonic), 243, 270, 308, 38 Special amongst others, all performed like lead in terms of grouping and upon impact/penetration into ballistic gel.